1. Environmental significance of PET release film

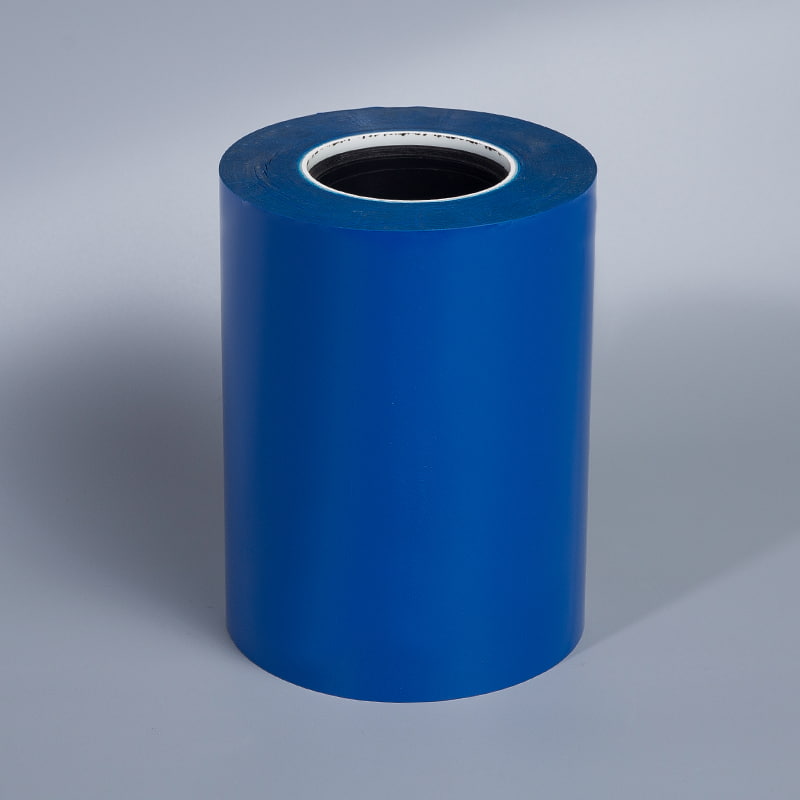

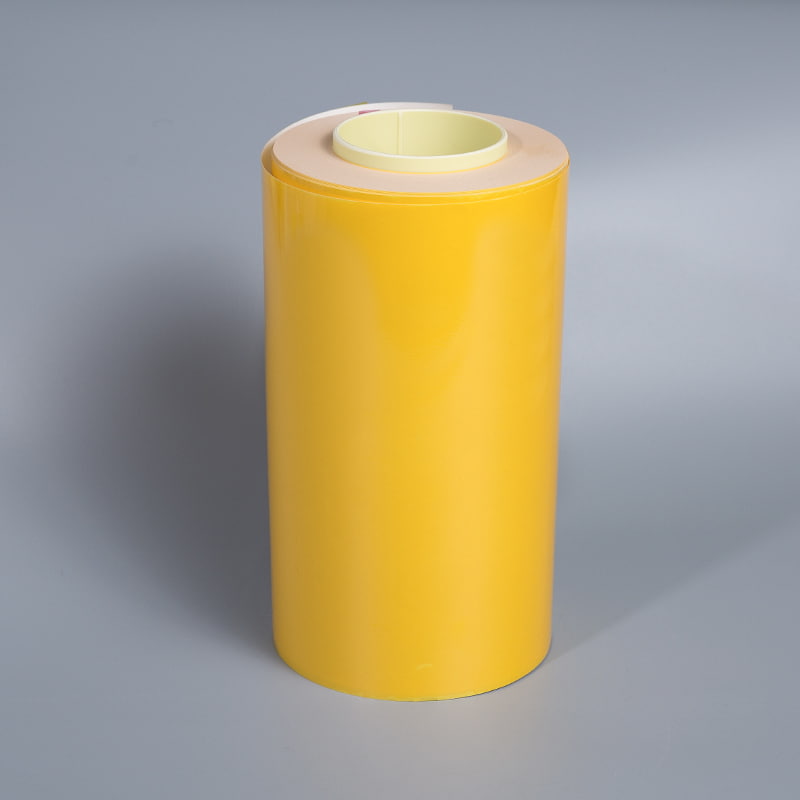

PET release film, also known as polyethylene terephthalate release film, is a thin film material with good physical properties. It has the advantages of high temperature resistance, moisture resistance and tear resistance. It is widely used in protecting electronic components, making labels and tapes, etc. However, due to its multi-layer structure and the fact that the surface is often coated with silicone oil or other coatings, it is difficult to degrade directly, so scientific recycling and reuse have become an important way to reduce its environmental impact.

2. Recycling challenges of PET release film

The recycling of PET release film is not easy. The difficulties in recycling are mainly concentrated in two aspects: first, there are often adhesive or coating residues on the surface; second, the multi-layer structure of the release film makes material separation complicated. In order to solve these problems, when recycling PET release film, the first task is to clean and separate its surface.

3. Cleaning: the first step in recycling PET release film

The surface of PET release film is usually coated with a release agent, such as silicone oil coating, to ensure that it has good release performance during use. In addition, it often comes into contact with adhesives or other materials during use, causing residues. These residues not only affect the recycling effect of the release film, but may also reduce the quality of recycled plastic particles. Therefore, cleaning is the first step in recycling.

1. Cleaning process

In order to ensure that PET materials can be effectively recycled, appropriate cleaning techniques must be used to remove surface coatings and adhesive residues. At present, commonly used cleaning methods include solvent cleaning and physical scrubbing. Solvent cleaning can dissolve coatings and residues, while physical scrubbing peels them off by mechanical means. In practical applications, a combination of multiple cleaning methods is often required to ensure that the PET release film is thoroughly cleaned.

2. Separation after cleaning

The cleaned PET release film usually requires further separation operations to remove any other impurities that may be present. This process ensures the purity of the PET material so that it can meet the ideal quality standards in the subsequent recycling process. Through cleaning and separation, the discarded PET release film is converted into a renewable base material and enters the next step of the recycled particle manufacturing process.

4. Recycled granule manufacturing: the transformation path of PET release film

After cleaning and separation, the PET release film will enter the physical regeneration stage, that is, through steps such as crushing and melting, it will be converted into reusable recycled plastic particles.

1. Crushing process

The cleaned PET release film is first sent to the crushing equipment for mechanical crushing. This step processes the release film into smaller particles for subsequent processing. Through crushing, the volume of PET material is greatly reduced, which is convenient for transportation and storage, and also lays the foundation for the subsequent melting step.

2. Melting regeneration

After crushing, the PET particles are sent to the melting equipment and converted into liquid by heating. This process is usually carried out at high temperature, allowing the PET material to be reshaped. During the melting stage, any remaining impurities or impurities will be removed through further filtering or separation steps to ensure the purity of the final recycled particles.

3. Granulation molding

The melted PET material is cooled and extruded to form new plastic particles. These recycled particles can be used to manufacture a variety of products, such as fibers, packaging materials, engineering plastics, etc. In some cases, these recycled particles can also be used to produce new release films, forming a closed-loop recycling system.

4. Application prospects of recycled particles

The application of recycled PET particles is very extensive. In the packaging industry, these particles can be used to make new plastic bottles, food packaging films and other products; in the textile industry, PET recycled fibers are used to make clothing and household items; in the industrial field, recycled particles can also be used in the production of high-performance plastic parts to meet the needs of environmentally friendly materials in different fields.

The PET release film made by cleaning and recycling particles not only reduces resource waste, but also reduces the burden of plastic on the environment. In the future, with the continuous advancement of technology, the recycling process of PET release film will be more efficient and the recycling rate will be further improved.

5. Future prospects

With the increasing global attention to environmental protection, the recycling and reuse of PET release film will inevitably become an important development direction. In the future, more companies will adopt advanced cleaning and recycling technologies to promote the recycling of PET release film. The improvement of policies and consumers' environmental awareness will further promote the development of these technologies.