PET Release Printed Films' high-definition printing technology in the field of food packaging does have the potential to promote more environmentally friendly design, while meeting the brand's demand for high-quality visual effects. The following is an analysis:

1. Driving force for environmentally friendly design

Sustainable materials:

Recyclability: PET material itself is a recyclable plastic that can effectively reduce the impact of packaging waste on the environment.

Lightweight: Compared with traditional heavy materials, PET film is lighter, reducing material usage and carbon footprint.

Compatible with environmentally friendly inks: PET film can be used with environmentally friendly water-based or solvent-free inks to achieve green printing.

Reduced resource waste:

High-precision printing reduces losses: High-definition printing technology reduces the need for multiple printings and improves the utilization efficiency of materials.

Integrated functions: PET Release Printed Films has the ability to provide protection, decoration and demolding functions at the same time, reducing the need for additional layers of materials.

2. Meet high-quality visual effects

Advantages of high-definition printing:

High-resolution patterns: PET film supports fine printing details and rich colors, which can accurately convey brand design.

Printing consistency: The dimensional stability of PET materials ensures the consistency of patterns in large-scale printing.

Anti-scratch performance: The printed surface is wear-resistant, protecting the pattern from being bright and clear for a long time.

Meet brand design needs:

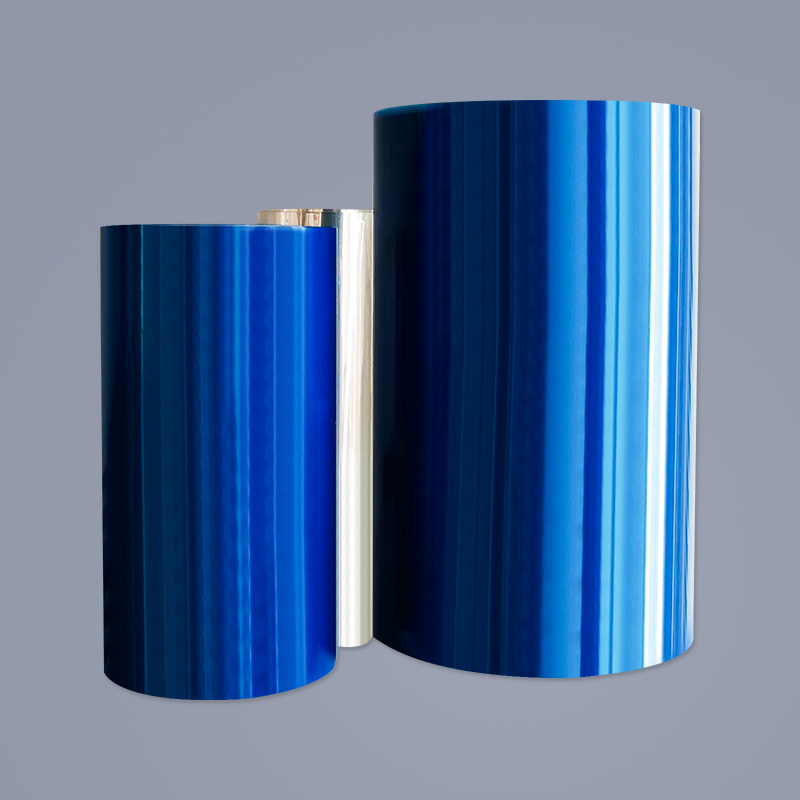

Diverse surface effects: PET film can provide options such as matte, glossy, and metallic effects to enhance the visual appeal of packaging.

Customization: Combined with the characteristics of release film, it can be used for transfer printing of complex patterns and multi-level design to meet brand differentiation needs.